Introduction

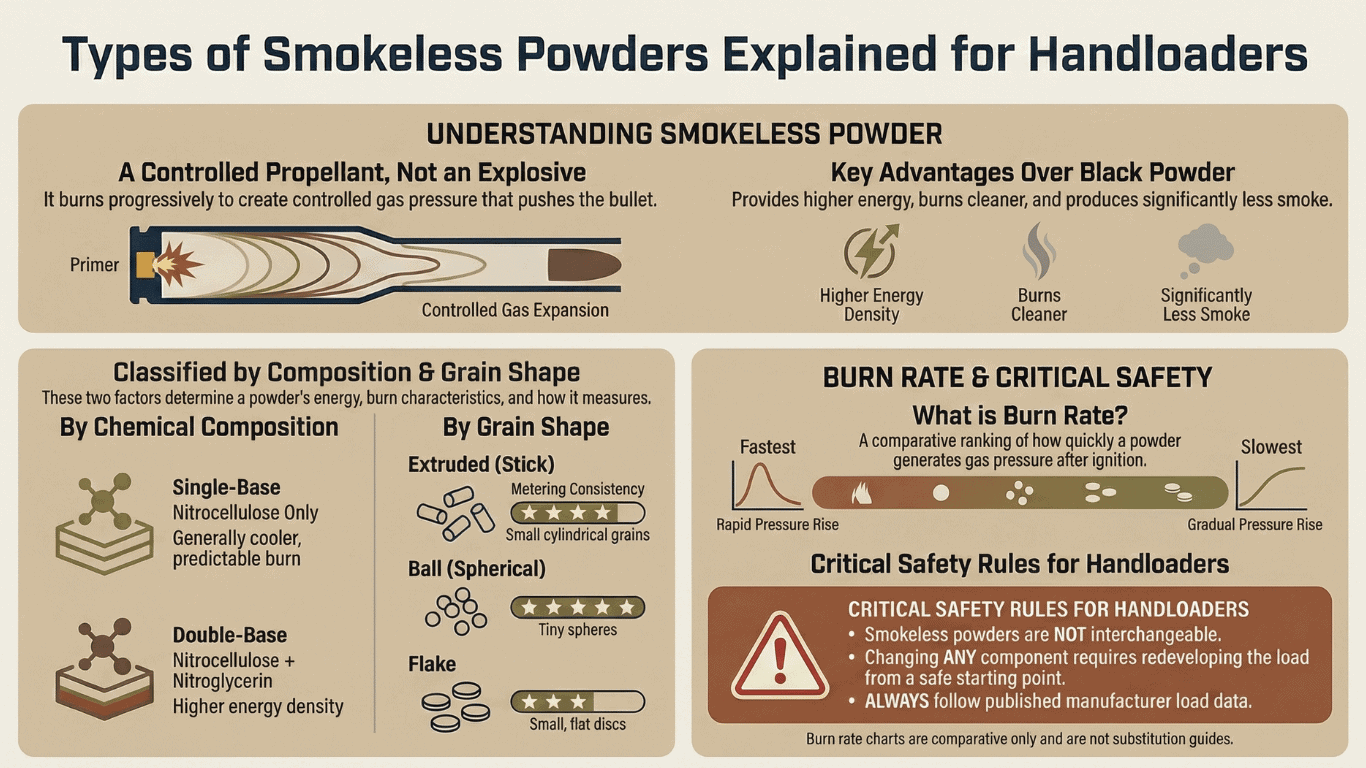

Understanding the various types of smokeless powder represents critical knowledge for safe and effective reloading. Each powder type in the smokeless powder family delivers distinct characteristics in composition, shape, and burn behavior, differences that directly control pressure development, velocity generation, and firing safety.

This comprehensive guide examines the fundamental categories and types of smokeless powder used in handloading, explaining why recognizing these smokeless powder variations matters before selecting load data or making component substitutions. Reloaders new to handloading or seeking broader foundation knowledge on equipment, components, and safety principles may find our Reloading 101 guide helpful before exploring powder type selection in detail.

What Is Smokeless Powder?

Smokeless powder constitutes a specialized class of propellant designed to burn progressively rather than detonate instantaneously. When ignited inside a cartridge case, smokeless powder generates controlled expanding gas that drives the bullet through the bore with precise pressure curves.

Despite the designation “smokeless,” these powder types do produce visible smoke during combustion. The term distinguishes modern smokeless powder formulations from historical black powder, which generates substantially more residue and barrel fouling.

For reloaders working with different types of smokeless powder, each formulation must be handled as high-energy explosive material whose performance characteristics depend on specific composition, grain geometry, and loading parameters.

Single-Base vs Double-Base Powders

Chemical composition creates one of the most significant distinctions among types of smokeless powder available to reloaders.

Single-Base Powders

Single-base powder types contain nitrocellulose as their primary explosive component. These smokeless powder formulations typically burn at lower temperatures and demonstrate more predictable pressure development curves. Single-base powder variants appear frequently in rifle cartridge applications where consistent pressure generation is essential.

Double-Base Powders

Double-base powder types incorporate both nitrocellulose and nitroglycerin in their chemical structure. These smokeless powder formulations deliver higher energy density per grain weight and often produce superior velocities using smaller powder charges. Double-base powder varieties can exhibit greater temperature sensitivity compared to single-base alternatives.

Neither powder type proves inherently superior to the other. Each smokeless powder category is specifically engineered for particular applications, operating pressure ranges, and cartridge designs.

Powder Shapes and Why They Matter

Physical geometry creates another important classification system for types of smokeless powder. Grain shape significantly influences how powder meters through equipment, igites under primer flash, and burns throughout pressure development.

Extruded (Stick) Powders

Extruded powder types feature cylindrical grain shapes that provide consistent ignition and controlled burn characteristics. These stick-shaped smokeless powder varieties appear frequently in rifle cartridge applications where progressive burning is required. Extruded powder types may meter less smoothly through certain powder measuring devices due to their elongated grain geometry.

Ball (Spherical) Powders

Ball powder types consist of small, spherical granules that meter with exceptional consistency through powder measuring equipment. These spherical smokeless powder varieties often require robust primer ignition systems and appear commonly in high-volume pistol and rifle loading operations where metering precision is prioritized.

Flake Powders

Flake powder types feature thin, flat grain geometry that ignites rapidly under primer flash. These disc-shaped smokeless powder varieties appear frequently in pistol and shotgun applications where fast pressure development is desired. Flake powder types typically serve fast-burning applications requiring quick energy release.

Grain shape alone does not determine burn rate characteristics or pressure development patterns. Physical geometry represents one engineering factor among many in smokeless powder design and performance.

Burn Rate Categories Explained

Burn rate classification describes how rapidly different types of smokeless powder release their stored energy, not the velocity imparted to projectiles. Understanding burn rate categories helps reloaders select appropriate powder types for specific cartridge applications.

Smokeless powder types are commonly classified as:

- Fast-burning powder types for pistol cartridges and light loads

- Medium-burning powder types for intermediate cartridge applications

- Slow-burning powder types for large rifle cartridges and heavy bullets

Published burn rate charts serve as relative comparison tools, not absolute performance rankings. Two smokeless powder types listed adjacently on burn rate charts may behave dramatically differently under actual firing pressures.

This variability explains why different types of smokeless powder cannot be substituted based solely on burn rate chart positions.

Why Smokeless Powders Are Not Interchangeable

Two seemingly similar types of smokeless powder may generate drastically different pressure curves and safety outcomes when substituted for one another.

Critical factors preventing safe substitution among smokeless powder types include:

- Energy density variations between powder formulations

- Grain geometry differences affecting burn progression

- Deterrent coating applications controlling burn rates

- Intended operating pressure ranges for specific powder types

Using incorrect powder types, even those with apparently similar burn rate classifications, can cause dangerous pressure spikes exceeding cartridge design limits. Published load data exists specifically to account for differences in energy density, grain geometry, and intended operating pressures among various types of smokeless powder. These safety protocols ensure cartridge pressures remain within established industry limits defined through ANSI/SAAMI standards, which exist to promote safe and consistent ammunition performance.

Safety Fundamentals Every Reloader Should Understand

Working safely with different types of smokeless powder requires strict adherence to established protocols:

- Never mix different smokeless powder types in the same container

- Keep all powder types in original labeled containers with lot information

- Label powder measuring equipment during loading sessions to prevent contamination

- Store different smokeless powder types in cool, dry environments away from ignition sources

- Track lot numbers when developing loads with specific powder types

Smokeless powder types remain stable when handled according to established safety procedures, but identification errors or unauthorized substitutions carry serious injury risk.

How This Knowledge Applies to Load Data

Understanding the distinctions among types of smokeless powder enables reloaders to:

- Select appropriate load data for specific powder types

- Avoid dangerous substitutions between different smokeless powder categories

- Interpret pressure signs correctly based on powder type characteristics

- Maintain loading consistency across different environmental conditions

Fundamental knowledge about smokeless powder types does not replace published load manuals. This understanding explains why load manuals exist and why deviations from published data for specific powder types create safety hazards.

Summary

The various types of smokeless powder differ significantly in chemical composition, physical shape, and combustion behavior. These differences are intentionally engineered for specific cartridge applications and pressure requirements. Reloaders who understand these fundamental distinctions among smokeless powder types are better equipped to load ammunition safely, consistently, and responsibly while achieving desired performance goals.